GM9S80 Installation Manual: Article Plan

This manual details the installation of Goodman GM9S80 furnaces (40k & 80k BTU)․ It covers safety, setup, venting, gas/electrical connections, and troubleshooting,

plus warranty registration details․

The Goodman GM9S80 is a highly efficient, 80% Annual Fuel Utilization Efficiency (AFUE) gas furnace designed for reliable and comfortable home heating․ Available in both 40,000 and 80,000 BTU models (GM9S800403AX and GM9S800804BU respectively), it’s a versatile choice for a wide range of residential applications․ This furnace features ultra-low NOx operation, contributing to cleaner air quality and compliance with stringent emissions standards․

This single-stage furnace prioritizes simplicity and durability, offering consistent performance you can depend on․ The GM9S80 incorporates continuous system monitoring, storing diagnostic codes for efficient troubleshooting, indicated by a flashing LED․ Goodman prioritizes customer satisfaction, backing the GM9S80 with a 10-year limited parts warranty upon timely online registration – a standard 5-year warranty applies if registration isn’t completed within 60 days of installation․ Detailed specifications, including dimensions and input/output capacities, are available in the accompanying specification sheet․ Proper installation, following this manual, is crucial for optimal performance and warranty validity․

Safety Precautions

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage․ Installation and service must be performed by a qualified, licensed HVAC technician familiar with this equipment and applicable codes․

Before commencing any work, disconnect electrical power to the furnace at the breaker panel․ Always verify power is OFF with a reliable testing device․ Gas supply must also be shut off and properly tagged․ Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and work boots․ Be mindful of sharp edges on the furnace cabinet and ductwork․

Carbon monoxide (CO) is a dangerous byproduct of combustion․ Ensure proper venting is established and functioning correctly to prevent CO buildup․ Never operate the furnace without a properly connected vent system․ Follow all local and national codes regarding gas and electrical installations․ Be aware of your surroundings and maintain a clean, organized work area to prevent trips and falls․ Refer to the complete installation manual for detailed safety guidelines and warnings․

Unpacking and Inspection

Upon delivery, carefully inspect the shipping container for any signs of damage during transit․ Note any visible damage on the delivery receipt before signing․ Once the unit is moved to the installation location, carefully unpack the GM9S80 furnace․ Use a utility knife to carefully open the packaging, avoiding damage to the unit itself․

Thoroughly inspect the furnace for any shipping damage, including dents, scratches, or missing components․ Compare the contents against the parts list included in the installation manual․ Report any discrepancies or damage immediately to the carrier and your Goodman distributor․ Do not attempt to operate a damaged furnace․

Verify that all accessories, such as the control board, wiring harnesses, and venting components, are present and undamaged․ Retain all packaging materials until the installation is complete and you are satisfied with the condition of the unit․ Proper documentation of any damage is crucial for warranty claims․

Tools and Materials Required

Successful GM9S80 installation necessitates a comprehensive toolkit․ Essential hand tools include screwdrivers (various types), wrenches (pipe and adjustable), pliers, wire strippers/crimpers, and a level․ Power tools such as a drill with assorted bits, a hole saw (for venting), and a voltage tester are also crucial․

Beyond tools, specific materials are needed․ These encompass gas piping components (black iron pipe, fittings, sealant approved for gas lines), venting materials (appropriate diameter pipe, elbows, termination cap), electrical wiring (Romex, connectors), and potentially, a condensate drain line and fittings․

Safety equipment is paramount: wear safety glasses, gloves, and appropriate footwear․ A manometer is required for proper gas pressure adjustment․ A carbon monoxide detector is vital for initial startup and testing․ Finally, have a supply of sheet metal screws, duct tape, and insulation readily available for ductwork connections․ Always consult local codes for specific material requirements․

Furnace Location and Installation Requirements

Proper GM9S80 placement is critical for safe and efficient operation․ The furnace must be installed in a dedicated space, free from combustible materials․ Refer to the physical dimensions and clearance requirements (detailed elsewhere in this manual) to ensure adequate space around the unit for servicing and airflow․

The installation area should have a level, stable floor capable of supporting the furnace’s weight․ Access for future maintenance is essential; allow sufficient room for removing panels and components․ Consider proximity to gas and electrical connections to minimize piping and wiring runs․

Adequate combustion air is vital․ Follow local codes regarding fresh air intake requirements․ Ensure the location allows for proper venting to the outdoors, adhering to all safety regulations․ Avoid installing the furnace in a location prone to moisture or freezing temperatures․ Always prioritize a well-ventilated, accessible, and structurally sound installation site․

Venting System Installation

Correct venting is paramount for safe GM9S80 operation, expelling combustion gases effectively․ Always adhere to local codes and the furnace’s specifications regarding vent pipe material, size, and slope․ Use only approved venting components designed for gas furnaces․

Ensure a proper seal at all vent connections to prevent leaks of potentially dangerous gases․ The vent system must terminate outdoors, away from windows, doors, and air intakes․ Maintain appropriate clearances from surrounding structures as specified in the installation guidelines․

Inspect the vent pipe for obstructions or damage before and after installation․ Proper pitch is crucial for condensate drainage, preventing corrosion and blockages․ Regularly check the venting system for leaks or deterioration․ Incorrect venting can lead to carbon monoxide poisoning; professional installation is strongly recommended․

Gas Piping Installation

Gas piping installation requires strict adherence to local codes and safety regulations․ A qualified and licensed gas fitter must perform all connections․ Before starting, ensure the gas supply is shut off and pressure is relieved․

Use appropriately sized gas piping to deliver the required BTU input for the GM9S80 model (40k or 80k)․ Black iron pipe or approved flexible gas connectors are typically used․ Apply pipe joint compound specifically designed for gas lines to all threaded connections, avoiding excess that could enter the gas valve․

Perform a thorough leak test using a soap solution after completing all connections․ Never use an open flame to check for leaks․ The gas valve should be equipped with a sediment trap to prevent debris from entering the valve․ Proper grounding of the gas piping system is also essential for safety․

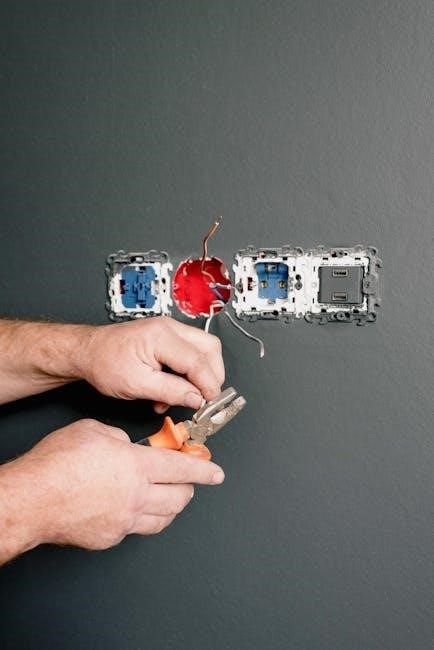

Electrical Connections

Electrical work must be performed by a qualified and licensed electrician, adhering to all local and national electrical codes․ Before commencing any electrical connections, always disconnect power to the circuit at the breaker panel․ Verify power is off using a reliable voltage tester․

The GM9S80 requires a dedicated electrical circuit with the correct voltage (typically 120V) and amperage, as specified on the unit’s nameplate․ Use appropriately sized wiring and overcurrent protection (fuses or circuit breakers)․ Ensure proper grounding of the furnace chassis to prevent electrical shock hazards․

All wiring connections should be made inside the designated electrical junction box․ Securely tighten all wire connectors to prevent loose connections and potential arcing․ Double-check all connections against the wiring diagram before restoring power․ Improper electrical connections can damage the furnace and create a fire hazard․

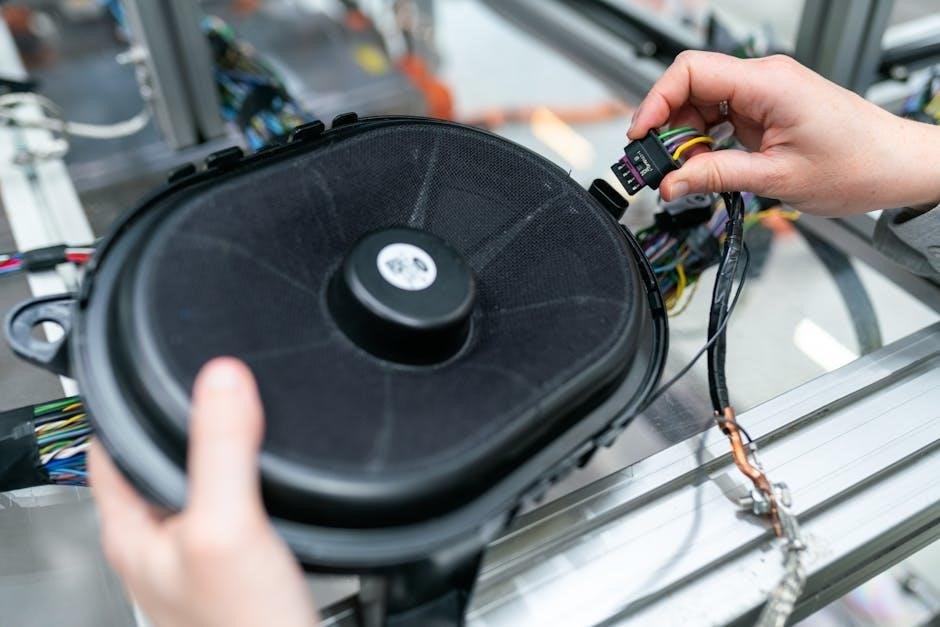

Wiring Diagram Overview

The GM9S80 wiring diagram, located on the inside of the unit’s access panel, is crucial for correct installation and troubleshooting․ It illustrates the connections between the furnace control board, the external power supply, the thermostat, and various safety and operating components․

Key elements depicted include the high-voltage wiring (120V) for the blower motor and control board, as well as the low-voltage wiring (24V) for the thermostat, gas valve, and safety switches․ Pay close attention to the color coding of the wires and the terminal designations on the control board․

Understanding the diagram allows for accurate identification of components and proper connection of wiring․ Incorrect wiring can lead to malfunction, damage, or safety hazards․ Refer to the diagram during electrical connections and when diagnosing issues․ A clear understanding of the wiring scheme is essential for a successful installation and ongoing maintenance․

Control Board Installation and Setup

The GM9S80’s control board is the central nervous system of the furnace, managing all operational functions․ Installation involves securely mounting the board within the designated compartment, ensuring proper grounding, and connecting all wiring according to the wiring diagram․

Before powering up, carefully verify all wire connections – double-checking for tightness and correct terminal placement is vital․ The control board stores diagnostic codes, accessible via the flashing LED indicators, aiding in troubleshooting․ Initial setup often involves configuring dip switches or jumpers to match the furnace model and gas type․

Proper setup ensures the furnace operates efficiently and safely․ Refer to the specific control board documentation for detailed instructions on configuration options․ After setup, perform a thorough system check to confirm correct operation of all components․ Incorrect configuration can lead to malfunctions or safety issues, so precision is key․

Blower Assembly Installation

The blower assembly is crucial for distributing heated air throughout the ductwork․ Installation begins with carefully positioning the blower housing within the furnace cabinet, ensuring proper alignment with the motor mounts․ The circulator blower motor, often an ECM (Electronically Commutated Motor) in GM9S80 models, must be securely fastened․

Before connecting the blower wheel, inspect it for any damage․ Once installed, verify the wheel spins freely without obstruction․ Electrical connections to the motor are critical; follow the wiring diagram precisely, paying attention to capacitor connections․ Proper grounding is essential for safety and optimal performance․

Ensure all screws are tightened to the manufacturer’s specifications․ After installation, check for proper motor operation and airflow․ An improperly installed blower can lead to reduced efficiency, noise, or even motor failure․ Refer to the specifications sheet for details on blower motor types and capacities․

Ductwork Connection

Proper ductwork connection is vital for efficient and effective heating․ Begin by ensuring all duct connections are clean, smooth, and free of obstructions․ Securely attach supply and return ductwork to the furnace cabinet using appropriate fasteners and sealant, preventing air leaks․

Insulate all exposed ductwork to minimize heat loss or gain, maximizing system efficiency․ Pay close attention to the size and configuration of the ductwork, ensuring it matches the furnace’s specifications and the building’s heating requirements․ Incorrectly sized ductwork can lead to airflow issues and reduced comfort․

Seal all joints and seams with duct mastic or approved foil tape – avoid using duct tape, as it degrades over time․ Verify proper airflow direction and volume after connection․ The GM9S80’s performance relies heavily on a well-sealed and properly sized duct system․ Consult the physical dimensions documentation for appropriate clearances․

Initial Startup and Checklist

Before initial startup, double-check all previous installation steps․ Verify gas piping is leak-free, electrical connections are secure, and the venting system is correctly installed․ Ensure the furnace cabinet is properly grounded and all access panels are in place․

Turn on the gas supply and check for any gas leaks using a leak detection solution․ Initiate the furnace following the control board’s startup sequence․ Observe the flame pattern for proper ignition and combustion․ Monitor the blower motor for smooth and quiet operation․

Use a checklist to confirm: Gas pressure is within specified limits, airflow is adequate, and the thermostat is communicating correctly with the furnace․ Note any unusual noises or error codes․ The GM9S80 continuously monitors system operation and stores diagnostic codes – familiarize yourself with the flashing LED indicators for quick troubleshooting․ Register the product online within 60 days to activate the 10-year limited parts warranty․

Thermostat Compatibility and Wiring

The Goodman GM9S80 furnace is compatible with a wide range of thermostats, including both mechanical and digital models․ However, for optimal performance and access to advanced features, a programmable or smart thermostat is recommended․ Confirm the thermostat’s voltage rating matches the furnace’s requirements – typically 24VAC․

Wiring is crucial for proper operation․ Standard wiring includes Rh, Rc, W, Y, G, and C terminals․ The ‘C’ (common) wire is often required for digital thermostats and provides continuous power․ Carefully follow the thermostat manufacturer’s wiring diagram and the GM9S80’s wiring diagram (refer to the dedicated section in this manual)․

Incorrect wiring can damage the furnace or thermostat․ Double-check all connections before energizing the system․ If using a heat pump thermostat, ensure the appropriate configuration is selected․ The GM9S80’s control board is designed to accommodate various thermostat types, but proper setup is essential for reliable heating and cooling control․

Diagnostic Codes and Troubleshooting

The GM9S80 furnace incorporates a self-diagnostic system that continuously monitors operation and stores error codes in memory․ These codes are invaluable for pinpointing the source of malfunctions, significantly reducing troubleshooting time․ A flashing LED indicator (see the ‘Flashing LED Indicators Explained’ section) signals the presence of a diagnostic code․

To retrieve the code, count the number of flashes and consult the diagnostic code table in this manual․ Common codes relate to issues with ignition, flame sensing, gas valve operation, blower motor function, or limit switch activation․

Before attempting repairs, always disconnect power to the furnace․ Refer to the troubleshooting guide for suggested solutions corresponding to each code․ If a code persists after attempting the recommended fixes, or if you are uncomfortable performing repairs, contact a qualified HVAC technician․ Ignoring diagnostic codes can lead to further damage or unsafe operating conditions․

Flashing LED Indicators Explained

The GM9S80 furnace utilizes a flashing LED indicator to communicate system status and diagnostic information․ This provides a quick visual assessment of the furnace’s operational condition without requiring specialized tools initially․ The LED is located on the control board, and its flashing pattern – the number of flashes and the pause between them – is crucial for interpretation․

A steady LED generally indicates normal operation․ However, any flashing pattern signifies a fault condition․ The number of flashes corresponds to a specific diagnostic code (refer to the ‘Diagnostic Codes and Troubleshooting’ section for a complete list)․ A rapid flash rate often indicates a more critical issue․

Carefully observe and count the flashes, noting the pause between sequences․ Documenting this pattern is essential for accurate troubleshooting․ If the LED continues to flash after power cycling the unit, consult the diagnostic code table to identify the problem and implement the appropriate corrective action․

Goodman Warranty Information (10-Year Limited)

Goodman offers a comprehensive warranty on the GM9S80 furnace, designed to provide peace of mind and protect your investment․ A 10-year limited parts warranty is available, but it’s contingent upon timely online registration of your product․ This extended warranty covers essential components against defects in materials and workmanship․

If the product is not registered online within 60 days of installation, the warranty automatically reverts to the standard 5-year limited parts warranty․ Therefore, prompt registration is crucial to maximize your coverage․ The online registration process is straightforward and can be completed via the Goodman website․

For complete details regarding the terms, conditions, and limitations of the warranty, please refer to the separate warranty sheet included within the manual’s ‘Manuals’ tab or available online․ This document outlines specific exclusions and requirements for valid warranty claims․ Maintaining proof of purchase is also essential․

GM9S80 Model Specifications (40k & 80k BTU)

The Goodman GM9S80 series encompasses both 40,000 BTU (GM9S800403AX) and 80,000 BTU (GM9S800804BU) models, catering to diverse heating demands․ Both units boast an 80% Annual Fuel Utilization Efficiency (AFUE) rating, ensuring efficient operation and cost savings․ These are single-stage, multi-position gas furnaces designed for reliable performance․

Detailed specifications are available in the comprehensive specification sheet, outlining heating input and output capacities․ Temperature rise ranges are also clearly defined, aiding in proper system design and installation․ The furnaces utilize a circulator blower, optimized for efficient airflow distribution throughout the connected ductwork․

The GM9S80 models are designed for compatibility with natural gas and propane, offering installation flexibility․ Refer to the full specification document for precise dimensions, weight, and electrical requirements․ Understanding these specifications is vital for a successful and compliant installation․

Physical Dimensions and Clearance Requirements

Proper installation necessitates adherence to specific physical dimension and clearance guidelines for the GM9S80 furnace․ Detailed dimensional drawings are crucial for planning the installation space and ensuring adequate airflow․ The unit’s footprint must be considered alongside necessary access for servicing and maintenance․

Critical clearances must be maintained around the furnace to prevent fire hazards and ensure safe operation․ These clearances pertain to combustible materials, including walls, ceilings, and other equipment․ Specific measurements for top, side, and front clearances are detailed in the installation manual and accompanying specification sheets․

Alternate inlet locations for gas and electrical connections are indicated on the dimensional drawings, providing flexibility during installation․ Pay close attention to the designated areas for high and low voltage access․ Maintaining these clearances is paramount for a safe, efficient, and code-compliant installation of the GM9S80 furnace․

Online Registration Process for Warranty

To activate the full 10-year limited parts warranty for your Goodman GM9S80 furnace, online registration is required within 60 days of the installation date․ Failure to register promptly will result in coverage reverting to the standard 5-year warranty period․ The registration process is straightforward and can be completed via the Goodman Manufacturing website․

Navigate to the Goodman website and locate the warranty registration section․ You will need the model number (GM9S800804BU or GM9S800403AX) and the serial number of your unit, which can be found on the furnace’s nameplate․ Accurate entry of this information is essential for successful registration․

Provide the installation date and your contact information․ Keep a copy of the registration confirmation for your records․ Access to the warranty documentation and further support resources are also available on the website․ Registering your GM9S80 ensures maximum protection and peace of mind․